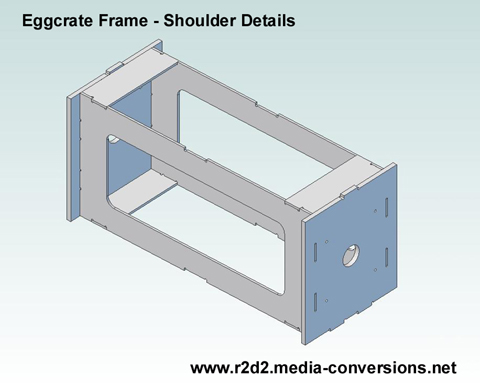

| Some

of the ribs have been left out of this image so that you can see how

the frame fits together. The eggcrate makes the frame almost completely

self aligning.Just remember to put the shoulder assembly in place

before you glue the top ring on!

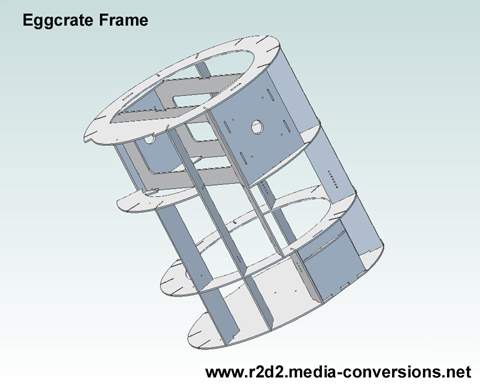

There

are 5 rings (numbered 0 to 5) to the frame. Ring 0 is actually the

skirt bottom. For now the frame is using two copies of Ring 1 for the

bottom. Rings 2 and 4 are continuous. Ring 3 is actually in 4 pieces.

Ring 3a fits between the front vents. Since it's alignment with the

skins can be difficult it is not slotted. Ring 3b fits above the coin

slots. Ring 3c, the largest segment, wraps around the sides and back of

the droid. Ring 3d fits below the utility arms.

There are 5 different ribs to the frame. See the ring2 drawing for notes where

each of the ribs go. The rib lettering corresponds to notes on the modified Body

Flat

Layout

Drawing that I posted on the R2BC site. Ribs a and

a-left go around the

front vents. There is no Rib b. Ribs c and c-left go between the

utility arms and the large

front doors. The left versions of those ribs have the extra slot for

Ring 3b. (one each, total 4 parts). Ribs d and e surround the shoulder

plates and the ankle insets. (4 each, total 8 parts). Ribs f and g are

the same, they are used on

the back of the droid (4 parts). There is only a drawing for Rib g.

The

image links to a 3d pdf file, click on it if you want to be able to

rotate the image around and examine it from other angles. (Note, the

3d.pdf file opens in a new window. If you have

problems with the 3d feature you may have to upgrade to the latest

version of Adobe Reader).

|