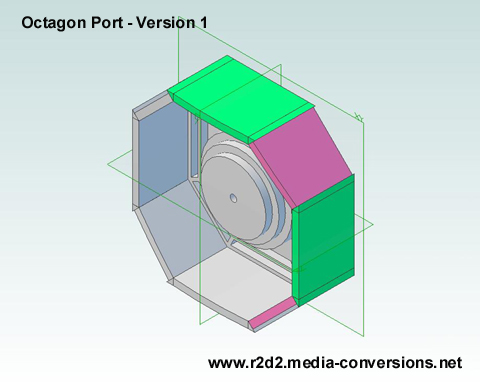

Click on the image for a 3D .pdf version.

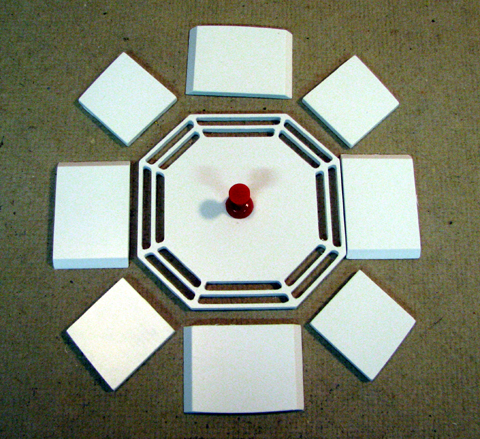

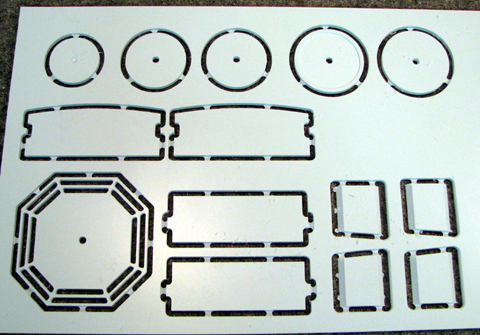

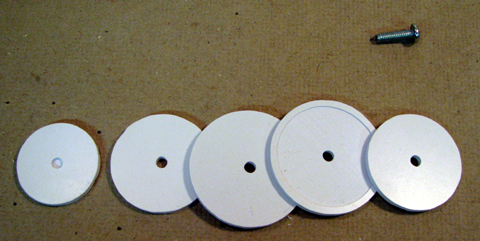

I cut a set of parts

But I didn't anticipate how hard it would be to keep them in alignment. - Back to the Drawing Board!

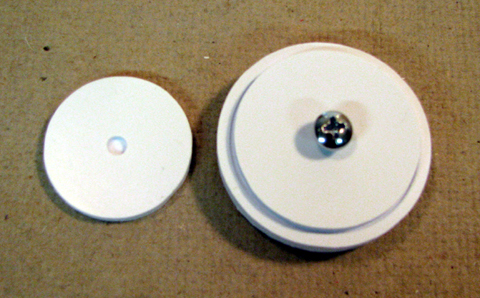

|  The stack of disks with an 8-32 screw for alignment |

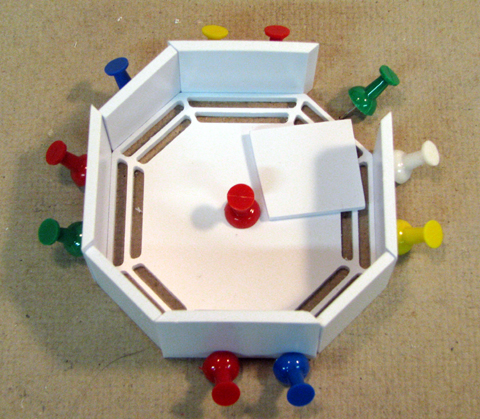

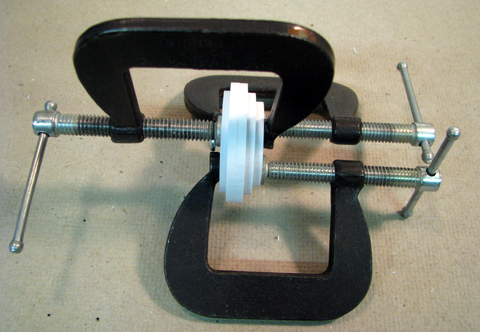

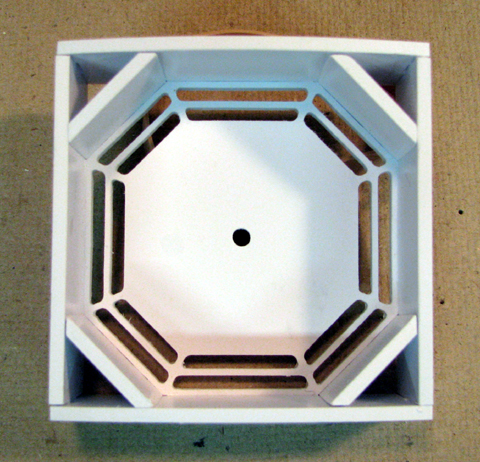

make sure the pocket is facing the bottom of the stack then clamp and glue |  |

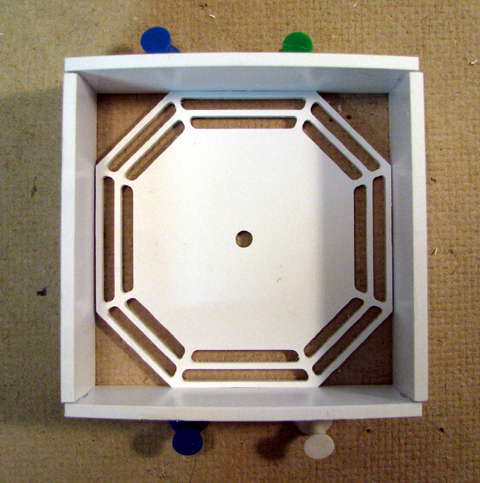

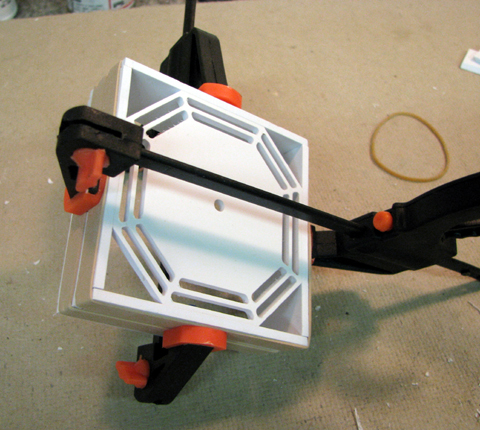

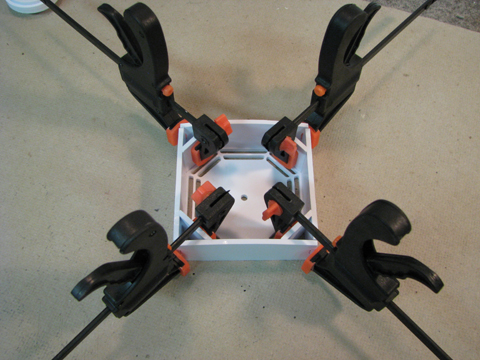

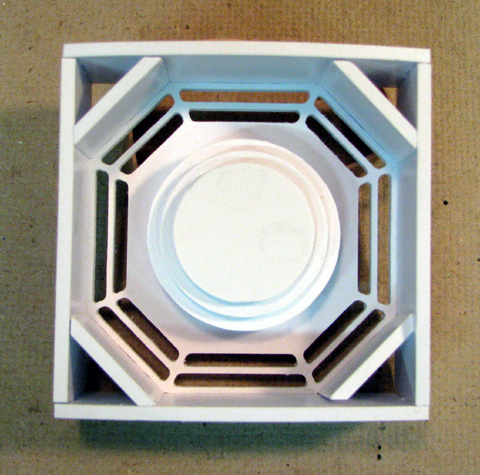

|  The tabs & slots with the rubber bands hold the box together. The clamps insure a tight joint. Apply glue just to the joints between the bottom and the sides. |

Insert the corners and glue the remainder of the joints. |  be careful how much force you use to clamp the corners It's not visible below, but I spread open one of the box edges which dosn't matter, since it's not visible when you mount the octagon port behind the skin. |

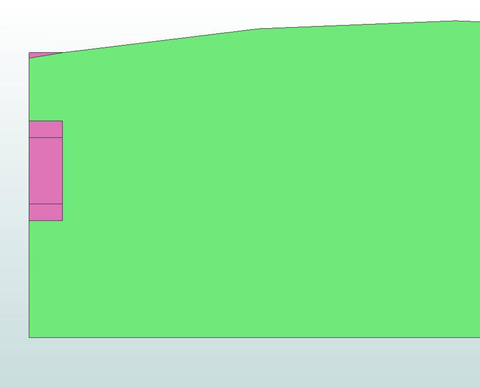

That little sliver of pink box edge will have to be filed off by hand to get a smooth fit to the skin |  |

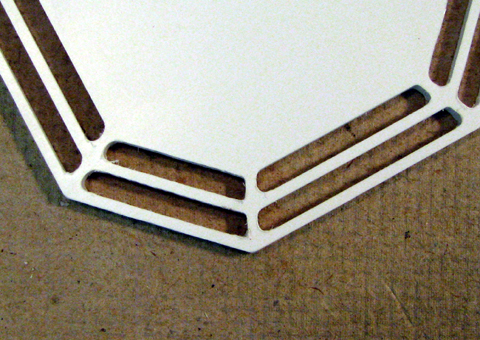

| Above: the disc stack in placed in for the photo. Paint first Left: The spider web slots are cut with a .0625 dia bit so they come out slightly rounded. A few minutes with a needle file sharpens up the outer corners. |

| Home |