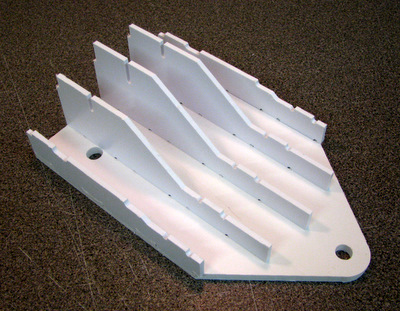

Right: the .125 panel.

The corners of the hex hole are slightly rounded. You'll need to sharpen them up a little for the coupling nut to fit easily. Do that before gluing so the nut can be used for alignment.

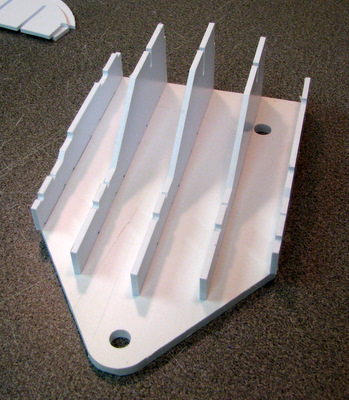

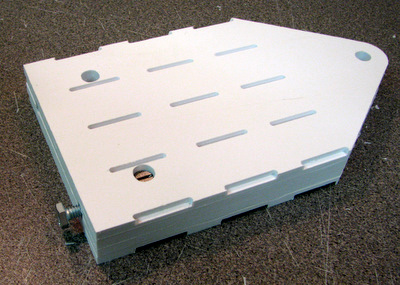

BEFORE you laminate the structural panels it's IMPORTANT to dry fit the ribs in the slots as shown to the right.

IF the fit is too tight, you have the opportunity to file the slots NOW. Once you laminate the parts the OPEN slots in the top panel become BLIND slots and you will have a very difficult time making them larger if the ribs don't fit!!!

Use the dowel pins and the shoulder bolt for alignment. Drip Weldon #3 through the slots in the .188 panels and through the holes in the .125 panel.

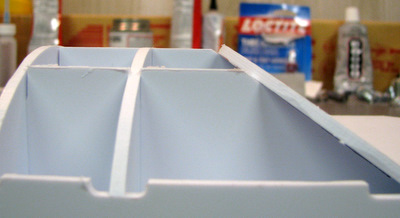

Right: If you are sloppy, like I am (the eyedropper I use to apply the Weldon Cement drips) you might find raised edges where the panel melted around a clamp. Sand those down so you get good joints when you laminate the panels.

There are glue holes in the outer panels for you to drip #3 Weldon into to get a better joint between the outer .188 assemblies and the inner .125 assembly

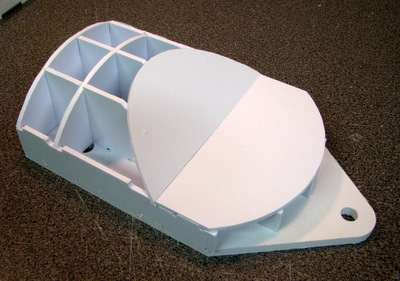

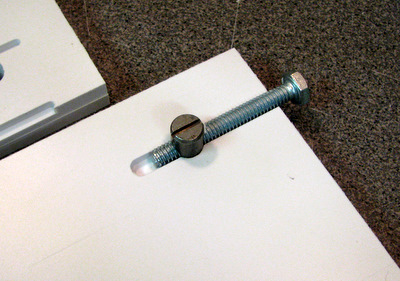

Left: the finished structural assembly. Next steps will be adding the eggcrate parts to finish the center ankle.

The hole for the Barrel Nut (also called a Dowel Nut) is 3/8 dia (nominal). It's threaded to take a 1/4-20 bolt (and the slot the bolt rides in is sized for a 1/4 in bolt). The center line of the Barrel Nut is 1.25 in from the edge of the ankle. There's a .5 inch additional space for the end of the bolt. In the pictures here I'm showing a 2 in 1/4-20 bolt. That's more than long enough to anchor into the 3/8 of plastic sheeting on R2's bottom.

I used "The Hillman Group 1/4 x 3/4 Plain Steel Standard (SAE) Barrel Nut" (it's hard to find 1 in Barrel nuts, and not necessary)

I got mine at Lowes - Item #: 137369 | Model #: 880544

Clear out the holes if any plastic has oozed out.

Insert the two barrel nuts. Use a small Phillips screwdriver to line up the holes.

Screw in a pair if 1/4 inch bolts. Since the ankle can be removed I like to lock the barrel nuts in position.

I use silicone glue. It stays flexible. Put some on each side of the barrel nuts. Once you put the skins on you no longer have access to the barrel nuts.