Engraved Skins

CS:R & CS:L Versions

UPDATE: 05/17/19 - updated to include availability of both CS:R and CS:L versions of skins in white. (04/16/20 - Black Skins are no longer available.)| All of the images above link to larger versions of the same image, just click on them. | |

|

|

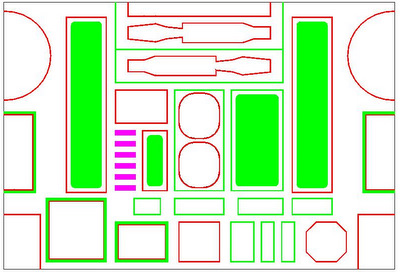

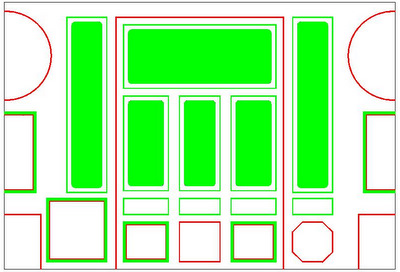

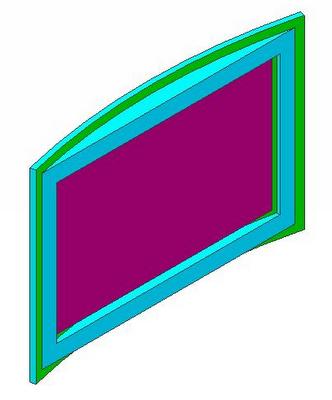

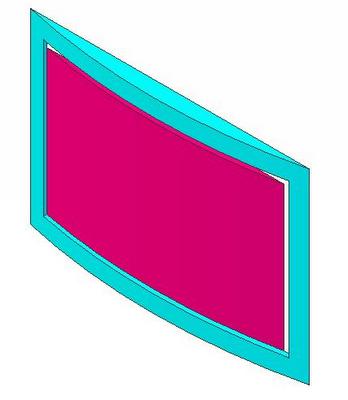

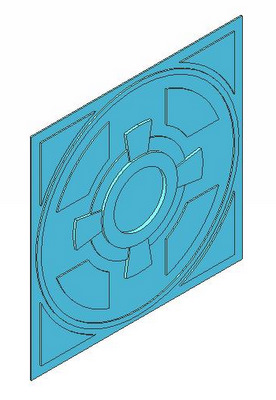

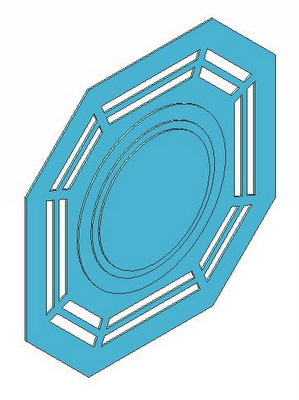

start with a door cut into the skins |  add a door backer to hold the curve of the skins |

add a fame around the backer that provides a lip for the door to close against |  here's a view of the backer and frame from the front without the skins |

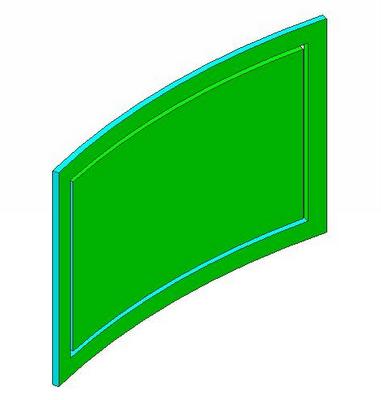

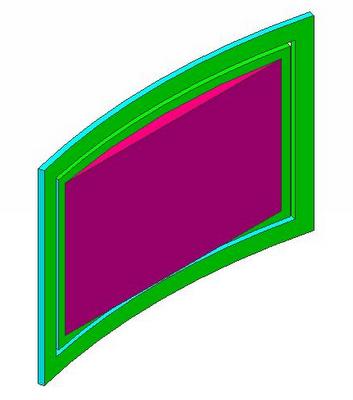

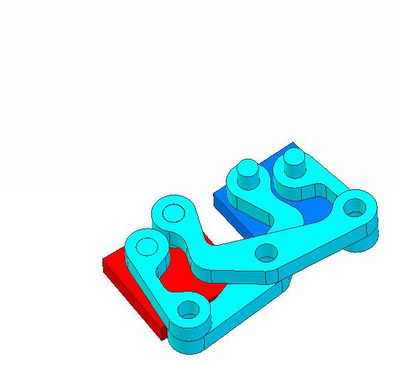

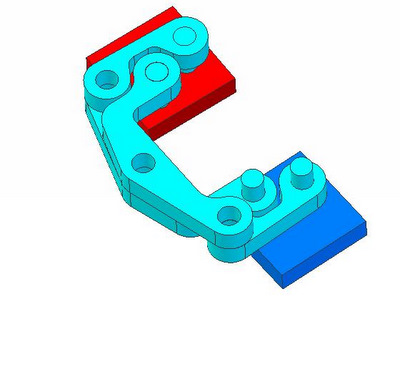

We start with the door (attached to the red square) closed . The blue square is mounted to the frame. |  Here the door has been rotated to the 1/2 open position. |

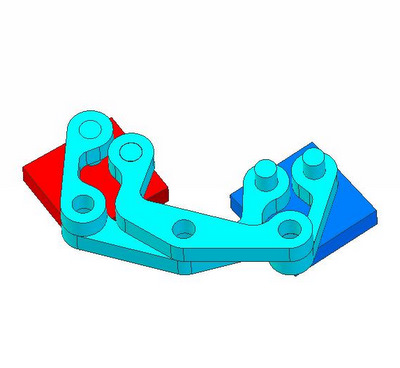

And in this image, the door is folded back, fully open. |

|  |

| Home |